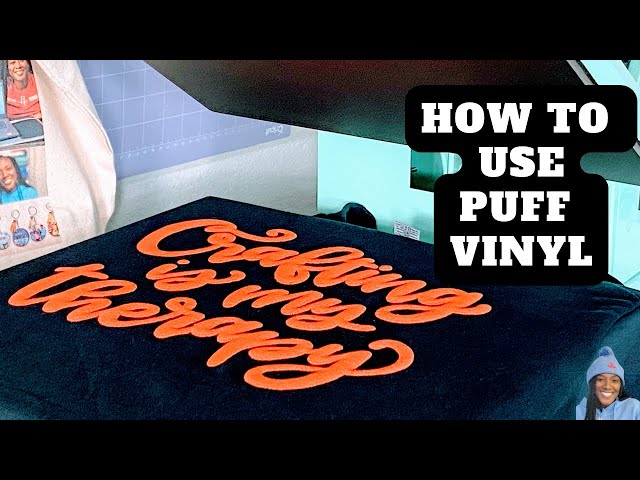

Cutting puff vinyl with a Cricut machine is a popular technique for creating custom designs on a variety of surfaces. Puff vinyl is a type of heat-transfer vinyl that has a raised, textured surface, giving it a unique look and feel. Here’s how you can cut puff vinyl on a Cricut machine:

Importance and Benefits: Cutting puff vinyl using a Cricut offers numerous advantages. It allows for precise and intricate designs, adds a unique tactile element to creations, and is suitable for various materials like fabrics, canvas, and wood. This technique adds personalization and style to items such as t-shirts, bags, home dcor, and more.

Main Article Topics:

- Materials Required: Puff vinyl, Cricut machine, cutting mat, weeding tool, heat press or iron

- Design Preparation: Creating or selecting a design, resizing and mirroring it for cutting

- Cutting the Vinyl: Loading the vinyl onto the cutting mat, adjusting the machine settings, and executing the cut

- Weeding the Vinyl: Removing the excess vinyl around the design

- Heat Application: Using a heat press or iron to adhere the vinyl to the desired surface

- Troubleshooting: Common issues and their solutions, such as vinyl not sticking or cutting cleanly

Contents

How to Cut Puff Vinyl on Cricut

Cutting puff vinyl with a Cricut machine involves several key aspects that contribute to the successful execution of the technique. Here are ten essential aspects to consider:

- Design Selection: Choosing a suitable design for the intended purpose and surface.

- Vinyl Quality: Using high-quality puff vinyl for optimal results.

- Machine Settings: Adjusting the Cricut machine settings according to the vinyl thickness and blade type.

- Cutting Precision: Ensuring precise cuts to maintain the design’s integrity.

- Weeding Accuracy: Carefully removing excess vinyl around the design.

- Heat Application: Using the correct temperature and pressure when applying the vinyl to the surface.

- Surface Preparation: Preparing the surface to ensure proper adhesion of the vinyl.

- Troubleshooting: Identifying and resolving common issues that may arise during the process.

- Versatility: Exploring the various applications of cut puff vinyl on different materials and surfaces.

- Creativity: Unleashing creativity to create unique and personalized designs.

These aspects are interconnected and essential for achieving successful results when cutting puff vinyl with a Cricut machine. Proper design selection, high-quality materials, precise cutting, and accurate weeding ensure the desired outcome. Understanding the machine settings and heat application techniques is crucial to avoid errors and ensure the vinyl adheres securely to the surface. Troubleshooting skills help resolve any issues that may arise, while versatility and creativity open up endless possibilities for customization and self-expression. By considering these key aspects, individuals can effectively master the art of cutting puff vinyl on their Cricut machines.

Design Selection

Design selection is a fundamental aspect of cutting puff vinyl on a Cricut machine, as it sets the foundation for the final outcome. Choosing the right design involves considering factors such as the intended purpose, the surface to be decorated, and the overall aesthetic desired.

- Compatibility with Purpose: Selecting a design that aligns with the intended purpose of the final product is crucial. For example, a design with intricate details might not be suitable for a t-shirt that will be frequently washed, as the details may fade or peel over time.

- Surface Considerations: The surface to be decorated plays a significant role in design selection. Different surfaces have varying textures, finishes, and heat tolerances. Choosing a design that complements the surface enhances the overall look and ensures proper adhesion.

- Design Complexity: The complexity of the design should be carefully evaluated based on the capabilities of the Cricut machine and the skill level of the user. Intricate designs may require more precise cutting and weeding, which can be challenging for beginners.

- Aesthetic Appeal: Ultimately, the design should align with the desired aesthetic. This involves considering factors such as color, shape, and overall style to create a visually appealing and cohesive end product.

By carefully considering these factors, users can select designs that are not only visually pleasing but also appropriate for the intended purpose and surface, ensuring successful and satisfying results when cutting puff vinyl with a Cricut machine.

Vinyl Quality

In the realm of cutting puff vinyl on a Cricut machine, the quality of the vinyl material plays a pivotal role in achieving optimal results. High-quality puff vinyl is characterized by its durability, dimensional stability, and ease of handling, all of which contribute to a successful cutting experience.

Using low-quality vinyl can lead to a myriad of issues. Inferior vinyl may tear or stretch during the cutting process, resulting in distorted or incomplete designs. Furthermore, poor-quality vinyl may not adhere properly to the surface, leading to peeling or lifted edges. This not only compromises the aesthetic appeal of the final product but also affects its longevity.

Conversely, investing in high-quality puff vinyl ensures precise cuts, effortless weeding, and strong adhesion. Premium vinyl is designed to withstand the pressure of the Cricut machine’s blade, resulting in clean and intricate cuts. Its dimensional stability prevents the vinyl from shrinking or expanding excessively, maintaining the design’s intended shape and size. Moreover, high-quality vinyl adheres securely to various surfaces, ensuring a durable and professional-looking finish.

Incorporating high-quality puff vinyl into the cutting process elevates the overall experience and outcome. It minimizes the risk of errors, frustrations, and wasted materials, allowing users to create stunning and long-lasting designs with confidence.

Machine Settings

The precise settings of a Cricut machine play a crucial role in the successful cutting of puff vinyl. These settings govern the pressure and speed at which the blade moves, directly impacting the quality and accuracy of the cuts. Adjusting the machine settings according to the specific thickness of the puff vinyl and the type of blade used ensures optimal performance and minimizes errors.

For instance, thicker puff vinyl requires a higher cutting pressure to achieve a clean and complete cut without tearing or distorting the material. Conversely, using a finer blade for intricate designs necessitates a lower cutting pressure to prevent the blade from digging too deeply into the vinyl and compromising the design’s integrity.

Understanding the relationship between machine settings, vinyl thickness, and blade type empowers users to make informed decisions, resulting in precise and professional-looking cuts. This understanding enables crafters to adapt their Cricut machines to the specific requirements of their projects, ensuring that the puff vinyl is cut to the desired depth and with the utmost accuracy. By mastering the art of adjusting machine settings, users can unlock the full potential of their Cricut machines and elevate their crafting skills.

Cutting Precision

In the realm of cutting puff vinyl with a Cricut machine, precision is paramount. Precise cuts are the foundation of successful designs, ensuring that intricate details are preserved, lines are sharp, and the overall aesthetic is uncompromised. Without cutting precision, even the most well-conceived designs can fall short, resulting in a distorted or unprofessional appearance.

Achieving cutting precision involves several key factors. First, the sharpness of the blade is crucial. A dull blade can tear or drag the vinyl, leading to rough edges and compromised design elements. Regularly replacing the blade ensures that it remains sharp and capable of delivering clean cuts.

Secondly, the cutting pressure must be carefully calibrated. Too much pressure can crush the vinyl, while too little pressure can result in incomplete cuts. The ideal pressure setting depends on the thickness of the vinyl being used. Thicker vinyl requires higher pressure, while thinner vinyl requires a lighter touch.

Finally, the cutting speed should be adjusted to complement the pressure setting. A slower cutting speed allows the blade to penetrate the vinyl more deeply, resulting in a cleaner cut. Conversely, a faster cutting speed is suitable for more delicate designs or thinner vinyl.

Mastering cutting precision empowers crafters to produce professional-quality designs with their Cricut machines. By understanding the interplay between blade sharpness, cutting pressure, and cutting speed, users can optimize their cutting process, ensuring that their puff vinyl projects are executed with the utmost precision and accuracy.

Weeding Accuracy

In the process of cutting puff vinyl with a Cricut machine, weeding accuracy stands as a crucial step that directly impacts the final outcome. It involves meticulously removing the excess vinyl around the design, leaving behind only the desired design elements. Achieving weeding accuracy is essential for several reasons:

Firstly, it ensures a clean and professional appearance. Excess vinyl around the design can create a messy and unfinished look, detracting from the overall aesthetic. By carefully weeding away this excess, crafters can achieve a polished and refined result.

Secondly, weeding accuracy prevents unwanted vinyl from adhering to the surface during the heat application process. This is particularly important for designs with intricate details or negative spaces, where excess vinyl can easily get trapped and ruin the design.

Moreover, precise weeding allows for better layering of different colors or designs. When multiple layers of vinyl are used, accurate weeding ensures that the layers align perfectly, creating a cohesive and visually appealing final product.

Mastering weeding accuracy requires a combination of patience, steady hands, and the right tools. Using a sharp weeding tool and taking the time to carefully remove the excess vinyl is essential. For intricate designs, a fine-tipped tool can provide greater precision.

In conclusion, weeding accuracy is an indispensable aspect of cutting puff vinyl with a Cricut machine. It ensures a clean and professional appearance, prevents unwanted vinyl adhesion, and allows for precise layering. By developing and refining their weeding skills, crafters can elevate their projects to the next level and create stunning puff vinyl designs with confidence.

Heat Application

In the realm of cutting puff vinyl with a Cricut machine, heat application emerges as a critical step that directly influences the success and longevity of the final product. Applying the vinyl to the surface using the correct temperature and pressure ensures a strong and durable bond, preventing peeling or lifting over time.

- Temperature Accuracy: Precise temperature control is essential to achieve optimal adhesion. Each type of puff vinyl has its recommended heat setting, and adhering to these guidelines ensures that the vinyl adheres securely without scorching or melting.

- Pressure Application: Applying sufficient pressure during heat application helps to create a strong bond between the vinyl and the surface. This pressure forces the vinyl into the contours of the surface, ensuring maximum contact and preventing air bubbles or wrinkles.

- Time Management: The duration of heat application also plays a crucial role. Applying heat for too short a time may result in poor adhesion, while excessive heat can damage the vinyl or the surface.

- Surface Preparation: Prior to heat application, the surface should be properly prepared to enhance adhesion. This includes cleaning the surface to remove any dirt or debris and ensuring that it is dry and free from oils or contaminants.

By understanding and implementing the principles of heat application, crafters can ensure that their puff vinyl designs adherely and maintain their vibrant appearance over time. This attention to detail and precision is a hallmark of professional-quality crafting and elevates the outcome of any project that incorporates cut puff vinyl.

Surface Preparation

In the realm of cutting puff vinyl with a Cricut machine, surface preparation plays a pivotal role in ensuring the success and longevity of the final product. Proper surface preparation promotes strong adhesion of the vinyl to the intended surface, preventing peeling, lifting, or premature wear and tear.

- Cleaning and Degreasing: Prior to applying the vinyl, the surface should be thoroughly cleaned to remove any dirt, dust, oils, or contaminants. This ensures a clean and receptive surface for the adhesive to bond with.

- Smoothing and Leveling: The surface should be smooth and level to provide an even surface for the vinyl to adhere to. Any bumps or imperfections can create air pockets or gaps, weakening the bond between the vinyl and the surface.

- Matching Surface Compatibility: Different surfaces have varying degrees of compatibility with vinyl. Some surfaces, such as certain plastics or fabrics, may require special adhesives or primers to enhance adhesion.

- Testing and Adjustment: Before applying the vinyl to the entire surface, it is advisable to conduct a small test area to assess the adhesion and make any necessary adjustments to the surface preparation or application process.

By meticulously preparing the surface, crafters can create a solid foundation for their puff vinyl designs, ensuring that they adhere firmly and maintain their vibrant appearance over time. This attention to detail is a cornerstone of successful crafting and elevates the outcome of any project that incorporates cut puff vinyl.

Troubleshooting

In the realm of cutting puff vinyl with a Cricut machine, troubleshooting plays a critical role in ensuring a successful and seamless crafting experience. Common issues that may arise during the process can be effectively identified and resolved, allowing crafters to navigate challenges and achieve optimal results.

- Material Compatibility: Understanding the compatibility between the puff vinyl and the surface being decorated is essential. Some surfaces, such as certain plastics or fabrics, may require special adhesives or primers to ensure proper adhesion.

- Blade Selection and Settings: Choosing the appropriate blade and adjusting the cutting settings according to the thickness and type of puff vinyl is crucial. Using a dull blade or incorrect settings can lead to tearing, distortion, or incomplete cuts.

- Weeding Precision: Meticulous weeding involves carefully removing the excess vinyl around the design. Inaccurate weeding can result in unwanted vinyl adhering to the surface during heat application, compromising the final design.

- Heat Application Parameters: Applying the correct temperature and pressure during heat application is essential to create a strong and durable bond between the vinyl and the surface. Insufficient heat or pressure can lead to poor adhesion, while excessive heat can damage the vinyl or the surface.

By understanding and addressing common troubleshooting scenarios, crafters can proactively minimize errors and achieve professional-quality results when cutting puff vinyl with a Cricut machine. This systematic approach to troubleshooting empowers crafters to overcome challenges, refine their techniques, and consistently produce stunning and long-lasting vinyl creations.

Versatility

The versatility of cut puff vinyl is a significant aspect of its popularity, as it allows for a wide range of applications on different materials and surfaces. This versatility stems from the unique characteristics of puff vinyl, which combine durability, texture, and ease of use.

One of the primary advantages of cut puff vinyl is its ability to adhere to various materials, including fabrics, metals, plastics, and even wood. This makes it suitable for a diverse range of projects, from customizing clothing and accessories to creating home dcor and signage. The durability of puff vinyl ensures that these creations can withstand wear and tear, making them ideal for everyday use.

Furthermore, the textured surface of puff vinyl adds a unique tactile element to designs. This texture can be used to create eye-catching and visually appealing graphics, logos, and patterns. The raised surface of puff vinyl also provides a distinct sensory experience, making it a popular choice for applications such as children’s toys and educational materials.

Understanding the versatility of cut puff vinyl is crucial for maximizing its potential in various crafting and design projects. By exploring the different materials and surfaces that can be decorated with puff vinyl, users can unlock new possibilities for creative expression and functional applications.

In summary, the versatility of cut puff vinyl, coupled with its durability and textured surface, makes it an ideal material for a wide range of applications. From personalizing everyday items to creating professional-looking signage, the possibilities are endless with this versatile material.

Creativity

Creativity plays a pivotal role in the realm of cutting puff vinyl with a Cricut machine. It allows individuals to transcend the boundaries of conventional designs and craft truly unique and personalized creations. This aspect of puff vinyl cutting empowers users to express their individuality, add a touch of flair to everyday objects, and create meaningful and memorable items.

- Design Exploration: Creativity fuels the exploration of diverse design possibilities. With puff vinyl’s versatility, users can experiment with various shapes, patterns, and color combinations to bring their unique visions to life.

- Personalization: Creativity enables the creation of personalized designs that hold sentimental value or reflect individual tastes and preferences. By incorporating meaningful words, symbols, or images into their designs, users can create one-of-a-kind items that resonate on a personal level.

- Artistic Expression: Puff vinyl cutting provides a canvas for artistic expression, allowing users to showcase their creativity and artistic flair. The tactile nature of puff vinyl adds a new dimension to designs, inviting users to explore innovative ways of incorporating texture and depth into their creations.

- Imaginative Applications: Creativity knows no bounds when it comes to puff vinyl cutting. Users can extend their imaginations to create unique applications, such as custom phone cases, laptop skins, wall art, and even personalized jewelry.

In summary, creativity is an indispensable element in the world of puff vinyl cutting. It empowers users to break free from limitations, unleash their imaginations, and create truly unique and personalized designs that reflect their individuality and artistic vision.

Tips for Cutting Puff Vinyl on Cricut

Cutting puff vinyl with a Cricut machine offers a unique opportunity to create custom designs on various surfaces. To achieve the best results and unleash your creativity, consider these helpful tips:

Tip 1: Choose High-Quality Vinyl

The quality of the puff vinyl significantly impacts the outcome of your project. Opt for premium vinyl designed for Cricut machines to ensure clean cuts, easy weeding, and durability.

Tip 2: Calibrate Your Machine

Proper calibration of your Cricut machine is crucial for precise cuts. Adjust the blade depth and pressure settings according to the thickness and type of vinyl you’re using.

Tip 3: Use a Sharp Blade

A sharp blade ensures clean cuts without tearing or distorting the vinyl. Replace dull blades regularly to maintain optimal cutting performance.

Tip 4: Weed Carefully

Meticulously remove excess vinyl around the design to achieve a professional finish. Use a weeding tool with a fine tip for intricate designs.

Tip 5: Apply Heat Properly

Follow the recommended temperature and pressure settings for heat application. Insufficient heat may result in poor adhesion, while excessive heat can damage the vinyl.

Tip 6: Prepare the Surface

Clean and prepare the surface thoroughly before applying the vinyl. Remove any dirt, dust, or oils to ensure a strong bond.

Tip 7: Experiment with Designs

Explore different design possibilities to create unique and personalized projects. Combine colors, patterns, and textures to bring your creative vision to life.

Tip 8: Troubleshoot Common Issues

If you encounter any difficulties, refer to troubleshooting guides to identify and resolve common problems, such as tearing, lifting, or poor adhesion.

Incorporating these tips into your cutting process will enhance your skills, ensure successful projects, and open up endless creative possibilities with puff vinyl on your Cricut machine.

FAQs on Cutting Puff Vinyl with Cricut

Frequently asked questions and their answers provide valuable insights into the process of cutting puff vinyl with a Cricut machine, helping users achieve optimal results and overcome common challenges.

Question 1: What are the essential considerations when choosing puff vinyl for Cricut projects?

When selecting puff vinyl for Cricut machines, consider factors such as compatibility with your machine, thickness and intended use, color and texture options, and overall quality to ensure successful cutting and long-lasting results.

Question 2: How do I calibrate my Cricut machine for cutting puff vinyl?

Calibration ensures precise cuts. Refer to your machine’s manual or online resources for specific instructions on adjusting blade depth and pressure settings based on the vinyl’s thickness and type.

Question 3: What techniques ensure clean and accurate cuts when working with puff vinyl?

Use a sharp blade to prevent tearing or distortion. Maintain proper cutting pressure and speed to achieve clean cuts. Additionally, use a weeding tool to carefully remove excess vinyl around the design for a professional finish.

Question 4: How do I effectively heat-apply puff vinyl to various surfaces?

Follow the recommended temperature and pressure guidelines for heat application based on the vinyl’s specifications. Ensure the surface is clean and prepared to promote strong adhesion. Apply heat evenly to avoid scorching or damaging the vinyl or the surface.

Question 5: What are some common troubleshooting tips for cutting and applying puff vinyl?

If you experience issues such as tearing, lifting, or poor adhesion, check the blade sharpness, adjust cutting settings, ensure proper heat application, and address any surface preparation concerns.

Question 6: How can I expand my creativity and explore new possibilities with puff vinyl on Cricut machines?

Experiment with different colors, patterns, and textures to create unique designs. Combine puff vinyl with other materials like heat-transfer vinyl or cardstock for added depth. Utilize online resources and design software to find inspiration and refine your techniques.

By addressing these frequently asked questions, users can gain a deeper understanding of the process, troubleshoot common challenges, and enhance their skills in cutting puff vinyl with Cricut machines to create stunning and durable designs.

Summary: Cutting puff vinyl with a Cricut machine requires careful consideration of material selection, machine calibration, cutting techniques, heat application, troubleshooting, and creative exploration. Mastering these aspects empowers users to achieve professional-quality results and bring their unique designs to life.

Transition: To delve further into the art of cutting puff vinyl with Cricut machines, explore additional resources and tutorials to refine your techniques and unlock new creative possibilities.

Conclusion

In the realm of creative expression and customization, cutting puff vinyl with a Cricut machine has emerged as a transformative technique. This in-depth exploration has unveiled the intricacies of the process, providing valuable insights and practical guidance to help users achieve professional-quality results.

From selecting high-quality vinyl and calibrating the machine to understanding cutting techniques and heat application, each step plays a crucial role in ensuring precise cuts, clean weeding, and durable adhesion. Troubleshooting tips empower users to overcome common challenges, while creative exploration encourages experimentation and the realization of unique designs.

As you continue your journey in cutting puff vinyl with Cricut machines, embrace the opportunity to refine your skills, expand your creativity, and bring your designs to life. Remember, the possibilities are limitless, and with dedication and practice, you can unlock the full potential of this versatile material.

In the ever-evolving world of crafting and design, stay curious, seek inspiration, and continue to explore the vast array of techniques and materials available. By embracing the art of cutting puff vinyl with Cricut machines, you open up a world of creative possibilities and the satisfaction of crafting truly exceptional projects.

Youtube Video: