Heat transfer vinyl (HTV) is a type of vinyl that can be applied to wood using heat. It is a popular choice for creating custom signs, decals, and other decorative items. HTV is available in a variety of colors and finishes, and it can be cut into any shape or design. Best of all, it is relatively easy to use, making it a great option for both beginners and experienced crafters.

There are many benefits to using HTV on wood. First, it is a very durable material that will not fade or peel over time. Second, it is resistant to water and heat, making it ideal for outdoor use. Third, HTV is very easy to apply, and it can be removed without damaging the wood.

If you are looking for a way to add a personal touch to your home dcor, HTV is a great option. It is a versatile material that can be used to create a wide variety of projects, from simple signs to elaborate wall art. With a little creativity, you can use HTV to transform any piece of wood into a work of art.

Contents

Can I Use Heat Transfer Vinyl on Wood?

Heat transfer vinyl (HTV) is a versatile material that can be used to add custom designs to a variety of surfaces, including wood. Here are 9 key aspects to consider when using HTV on wood:

- Material: HTV is available in a variety of materials, including polyurethane, plastisol, and flock. The type of material you choose will depend on the look and feel you want for your project.

- Adhesion: HTV adheres to wood using heat and pressure. The amount of heat and pressure required will vary depending on the type of HTV you are using.

- Durability: HTV is a durable material that will not fade or peel over time. It is also resistant to water and heat, making it ideal for outdoor use.

- Opacity: HTV is available in both opaque and transparent finishes. Opaque HTV will completely cover the wood surface, while transparent HTV will allow the wood grain to show through.

- Color: HTV is available in a wide variety of colors, so you can find the perfect match for your project.

- Design: HTV can be cut into any shape or design using a craft cutter or die-cutting machine.

- Application: HTV is easy to apply to wood using a heat press. The heat press will apply the necessary heat and pressure to bond the HTV to the wood.

- Removal: HTV can be removed from wood using a heat gun or iron. The heat will soften the adhesive, allowing you to peel the HTV away from the wood.

- Care: HTV is easy to care for. Simply wipe it down with a damp cloth to clean it.

By understanding these key aspects, you can use HTV to create beautiful and durable custom designs on wood. For example, you can use HTV to create signs, decals, and even furniture. With a little creativity, there are endless possibilities for using HTV on wood.

Material

The type of HTV material you choose will have a significant impact on the final look and feel of your project. Here are three of the most common types of HTV materials and their unique characteristics:

- Polyurethane: Polyurethane is the most popular type of HTV. It is a durable and versatile material that is available in a wide range of colors and finishes. Polyurethane HTV is also relatively easy to apply, making it a good choice for beginners.

- Plastisol: Plastisol is a soft and flexible type of HTV. It is often used for creating raised or 3D designs. Plastisol HTV is also very durable and resistant to fading.

- Flock: Flock is a type of HTV that has a velvety texture. It is often used to create designs that have a soft and luxurious feel. Flock HTV is also very durable and easy to apply.

When choosing a HTV material for your wood project, it is important to consider the following factors:

- The look and feel you want for your project

- The durability of the material

- The ease of application

By understanding the different types of HTV materials and their unique characteristics, you can choose the right material for your project and achieve the desired results.

Adhesion

Adhesion is a critical component of using heat transfer vinyl (HTV) on wood. Without proper adhesion, the HTV will not bond to the wood surface and will eventually peel off. The amount of heat and pressure required to achieve proper adhesion will vary depending on the type of HTV you are using. Generally speaking, thicker HTV will require more heat and pressure than thinner HTV. It is important to follow the manufacturer’s instructions for the specific type of HTV you are using to ensure proper adhesion.

There are a few things you can do to improve the adhesion of HTV to wood. First, make sure the wood surface is clean and free of any dirt or debris. Second, use a heat press to apply the HTV to the wood. A heat press will provide the necessary heat and pressure to bond the HTV to the wood. Finally, allow the HTV to cool completely before peeling away the carrier sheet. This will help to ensure that the HTV has fully adhered to the wood.

By understanding the importance of adhesion and following the proper steps, you can ensure that your HTV projects will be successful.

Durability

The durability of HTV is one of its most important features, especially when using it on wood for outdoor applications. HTV is resistant to fading, peeling, water, and heat, which makes it an ideal choice for creating long-lasting outdoor signs, decals, and other decorative items.

For example, if you were to create a sign for your business using HTV, you could be confident that it would withstand the elements and remain looking its best for years to come. This is because HTV is not affected by UV rays, rain, or snow. It is also resistant to scratching and abrasion, so it can withstand even the most demanding conditions.

The durability of HTV makes it a great choice for a variety of outdoor applications, including:

- Signs

- Decals

- Banners

- Flags

- Vehicle wraps

If you are looking for a durable and long-lasting way to add custom designs to wood for outdoor use, HTV is a great option.

Opacity

The opacity of HTV is an important consideration when using it on wood, as it will affect the final look of your project. Opaque HTV will completely cover the wood surface, hiding the grain and any other imperfections. This can be a good choice if you want a solid color or design on your wood. Transparent HTV, on the other hand, will allow the wood grain to show through. This can be a good choice if you want to add a design to your wood while still preserving its natural beauty.

-

Facet 1: Opaque HTV

Opaque HTV is a good choice for creating solid color designs on wood. It is also a good choice for covering up imperfections in the wood.

-

Facet 2: Transparent HTV

Transparent HTV is a good choice for adding designs to wood while still preserving its natural beauty. It is also a good choice for creating layered designs.

Ultimately, the best way to decide which type of HTV to use on wood is to experiment and see what you like best. There is no right or wrong answer, it all depends on the look you are trying to achieve.

Color

The wide range of colors available for heat transfer vinyl (HTV) is a significant advantage when using it on wood. With HTV, you can create designs in any color you can imagine, making it a versatile choice for a variety of projects.

- Customization: The ability to choose from a wide variety of colors gives you the freedom to customize your wood projects to match your personal style or the specific requirements of your project.

- Matching: With so many colors available, you can easily find the perfect match for the wood you are using. This allows you to create seamless designs that blend in with the natural beauty of the wood.

- Accents: HTV can be used to add colorful accents to wood projects. This can be a great way to add a touch of personality or to highlight certain features of the wood.

- Variety: The wide range of colors available means that you can create a variety of different looks with HTV on wood. From simple one-color designs to complex multi-color designs, the possibilities are endless.

The availability of a wide range of colors is one of the things that makes HTV such a great choice for wood projects. With HTV, you can create custom designs that are both beautiful and durable.

Design

The ability to cut HTV into any shape or design is essential for using it on wood. This allows you to create custom designs that are perfectly suited to your project. For example, you could create a sign with your favorite quote, a decal with your company logo, or even a piece of wall art with an intricate design.

There are a few different ways to cut HTV. You can use a craft cutter, such as a Cricut or Silhouette machine, or you can use a die-cutting machine. If you are new to using HTV, a craft cutter is a good option. Craft cutters are relatively inexpensive and easy to use. However, if you plan on doing a lot of HTV projects, a die-cutting machine may be a better investment. Die-cutting machines are more expensive than craft cutters, but they are also more precise and can cut more intricate designs.

Once you have cut your HTV design, you can use a heat press to apply it to wood. Heat presses come in a variety of sizes and prices, so you can find one that is right for your needs. To use a heat press, simply place your HTV design on the wood and apply heat and pressure. The heat will bond the HTV to the wood, creating a permanent design.

The ability to cut HTV into any shape or design is one of the things that makes it such a versatile material for use on wood. With HTV, you can create custom designs that are both beautiful and durable.

Application

Applying heat transfer vinyl (HTV) to wood is a relatively simple process, especially with the use of a heat press. A heat press is a machine that applies both heat and pressure to the HTV, which helps to bond it to the wood. This process is much easier and more efficient than trying to apply HTV by hand, and it also helps to ensure that the HTV will adhere properly to the wood.

-

Facet 1: Understanding the Role of Heat and Pressure

Heat and pressure are both essential elements in the application of HTV to wood. The heat helps to soften the adhesive on the back of the HTV, which allows it to bond to the wood. The pressure helps to ensure that the HTV adheres evenly to the wood and that there are no air bubbles or wrinkles.

-

Facet 2: Choosing the Right Heat and Pressure Settings

The specific heat and pressure settings that you use will depend on the type of HTV that you are using and the type of wood that you are applying it to. It is important to follow the manufacturer’s instructions for the HTV that you are using. Generally speaking, however, you will want to use a heat setting that is high enough to soften the adhesive on the HTV, but not so high that it damages the HTV or the wood.

-

Facet 3: Using a Heat Press for Efficient Application

A heat press is the most efficient way to apply HTV to wood. Heat presses come in a variety of sizes and prices, so you can find one that is right for your needs. If you are only planning on doing a few small projects, you may be able to get away with using a small, hand-held heat press. However, if you are planning on doing larger projects or if you want to be able to apply HTV more quickly and efficiently, a larger, professional-grade heat press is a better investment.

-

Facet 4: Ensuring Proper Adhesion

Once you have applied HTV to wood, it is important to make sure that it has adhered properly. You can do this by gently peeling back a corner of the HTV. If the HTV peels away easily, it means that it has not adhered properly and you will need to reapply it. If the HTV does not peel away easily, it means that it has adhered properly and you are finished.

Applying HTV to wood is a great way to add custom designs and decorations to your wood projects. By following these tips, you can ensure that your HTV projects will be successful.

Removal

The ability to remove HTV from wood is an important consideration, especially if you are new to using HTV or if you are planning on using it for temporary applications. There are a few different ways to remove HTV from wood, but the most common and effective method is to use a heat gun or iron.

-

Facet 1: Understanding the Role of Heat

Heat is essential for removing HTV from wood. The heat will soften the adhesive on the back of the HTV, which will allow you to peel it away from the wood without damaging the wood.

-

Facet 2: Using a Heat Gun or Iron

A heat gun or iron is the most effective way to remove HTV from wood. Heat guns are more powerful than irons, so they can be used to remove HTV more quickly and easily. However, if you do not have a heat gun, you can use an iron on a high heat setting.

-

Facet 3: Peeling Away the HTV

Once you have heated the HTV, you can begin to peel it away from the wood. Start by peeling away a corner of the HTV. If the HTV peels away easily, you can continue to peel it away with your fingers. If the HTV does not peel away easily, you may need to use a tool, such as a tweezers or a craft knife, to help you peel it away.

-

Facet 4: Cleaning Up

Once you have removed the HTV from the wood, you may need to clean up any residual adhesive. You can do this by wiping the wood down with a cloth dampened with rubbing alcohol.

Removing HTV from wood is a relatively simple process, but it is important to do it carefully to avoid damaging the wood. By following these tips, you can remove HTV from wood quickly and easily.

Care

The ease of care associated with HTV is a significant advantage when considering its use on wood. The ability to maintain and clean HTV effortlessly contributes to its practicality and longevity.

- Effortless Maintenance: Unlike other materials that may require specific cleaning agents or complex maintenance routines, HTV can be effortlessly cleaned with a simple wipe using a damp cloth. This straightforward cleaning process ensures that your HTV designs remain pristine and vibrant over time.

- Preservation of Appearance: Regular cleaning with a damp cloth helps preserve the appearance of HTV on wood. By removing dust, dirt, and other contaminants, you prevent the accumulation of grime that can dull the surface of the HTV and compromise its aesthetic appeal.

- Prevention of Damage: Proper care and cleaning of HTV on wood surfaces help prevent damage. Neglecting to clean HTV can lead to the accumulation of dirt and debris, potentially causing scratches or discoloration. Regular cleaning maintains the integrity of the HTV and extends its lifespan.

- Enhanced Longevity: The ease of care for HTV on wood contributes to its overall longevity. By maintaining and cleaning the HTV surface regularly, you prolong its lifespan and ensure that your designs continue to enhance the appearance of your wood projects for years to come.

In conclusion, the effortless care and maintenance required for HTV on wood surfaces make it an ideal choice for various applications. Its simple cleaning process preserves its appearance, prevents damage, and enhances its longevity, ensuring that your HTV designs remain vibrant and visually appealing for an extended period.

Tips for Using Heat Transfer Vinyl on Wood

Heat transfer vinyl (HTV) is a versatile material that can be used to add custom designs to a variety of surfaces, including wood. However, there are a few things to keep in mind when using HTV on wood to ensure that your projects are successful.

Tip 1: Choose the Right Type of HTV

There are two main types of HTV: opaque and transparent. Opaque HTV will completely cover the wood surface, while transparent HTV will allow the wood grain to show through. Choose the type of HTV that best suits the look you are trying to achieve.

Tip 2: Use a Heat Press

A heat press is the best way to apply HTV to wood. Heat presses apply both heat and pressure, which helps to bond the HTV to the wood. If you do not have a heat press, you can use an iron, but be sure to use a high heat setting and apply pressure evenly.

Tip 3: Protect the HTV

Once you have applied the HTV to the wood, it is important to protect it from scratches and other damage. You can do this by applying a clear coat of polyurethane or another protective finish.

Tip 4: Clean the HTV Regularly

HTV is easy to clean. Simply wipe it down with a damp cloth to remove dust and dirt. Do not use harsh chemicals or abrasive cleaners, as these can damage the HTV.

Tip 5: Remove the HTV Carefully

If you need to remove the HTV from the wood, do so carefully. Use a heat gun or iron to soften the adhesive, and then peel the HTV away from the wood. Do not pull or tug on the HTV, as this can damage the wood.

By following these tips, you can ensure that your HTV projects on wood are successful and long-lasting.

Summary of Key Takeaways

- Choose the right type of HTV for your project.

- Use a heat press to apply HTV to wood.

- Protect the HTV from scratches and other damage.

- Clean the HTV regularly.

- Remove the HTV carefully if necessary.

Conclusion

Heat transfer vinyl is a versatile and easy-to-use material that can be used to add custom designs to wood. By following the tips in this article, you can ensure that your HTV projects are successful and long-lasting.

FAQs on Using Heat Transfer Vinyl (HTV) on Wood

This section addresses frequently asked questions (FAQs) about using heat transfer vinyl (HTV) on wood, providing informative answers to common concerns and misconceptions.

Question 1: Can I use any type of HTV on wood?

Answer: No, not all types of HTV are suitable for use on wood. It is recommended to choose a type of HTV that is specifically designed for wood, as it will adhere better and produce a more durable result.

Question 2: Do I need to use a heat press to apply HTV to wood?

Answer: Yes, using a heat press is the best way to apply HTV to wood. Heat presses provide both heat and pressure, which are necessary for properly bonding the HTV to the wood surface.

Question 3: How can I protect the HTV after it has been applied to wood?

Answer: To protect the HTV from scratches and other damage, it is advisable to apply a clear coat of polyurethane or another protective finish. This will help to seal and protect the HTV, ensuring its longevity.

Question 4: How do I clean HTV on wood?

Answer: Cleaning HTV on wood is simple. Use a damp cloth to wipe down the surface, removing any dust or dirt. Avoid harsh chemicals or abrasive cleaners, as these can damage the HTV.

Question 5: Can I remove HTV from wood if I make a mistake?

Answer: Yes, HTV can be removed from wood if necessary. Use a heat gun or iron to soften the adhesive, then carefully peel the HTV away from the wood. Do not pull or tug on the HTV, as this may damage the wood.

Question 6: What are some tips for using HTV on wood?

Answer: Here are a few tips for using HTV on wood:

- Choose the right type of HTV for your project.

- Use a heat press to apply HTV to wood.

- Protect the HTV from scratches and other damage.

- Clean the HTV regularly.

- Remove the HTV carefully if necessary.

Summary of Key Takeaways

Using HTV on wood requires careful consideration of the type of HTV used, the application method, and the subsequent care and maintenance. By following the guidelines and tips outlined in this FAQ section, you can achieve successful and durable HTV applications on wood.

Transition to the Next Article Section

This concludes the FAQ section on using heat transfer vinyl on wood. For further exploration, the next section delves into troubleshooting common issues that may arise when using HTV on wood.

Conclusion

In conclusion, the exploration of “can I use heat transfer vinyl on wood” has revealed the versatility and viability of this technique for adding custom designs and decorative elements to wooden surfaces. HTV offers a durable and cost-effective way to enhance wooden items with intricate designs, logos, and unique patterns.

By understanding the key aspects of using HTV on wood, including material selection, proper application, and subsequent care, individuals can achieve professional-looking results. The ability to customize wooden items with HTV opens up endless possibilities for personalized dcor, gift-making, and creative projects. As technology continues to advance, we can anticipate even more innovative applications and design options for HTV on wood, further expanding the realm of creative expression.

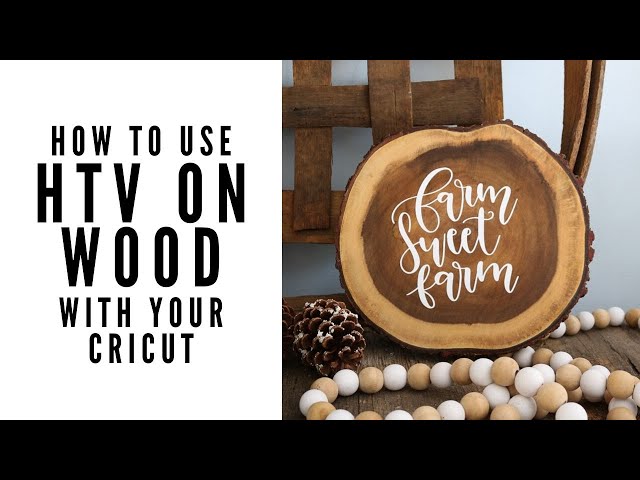

Youtube Video: